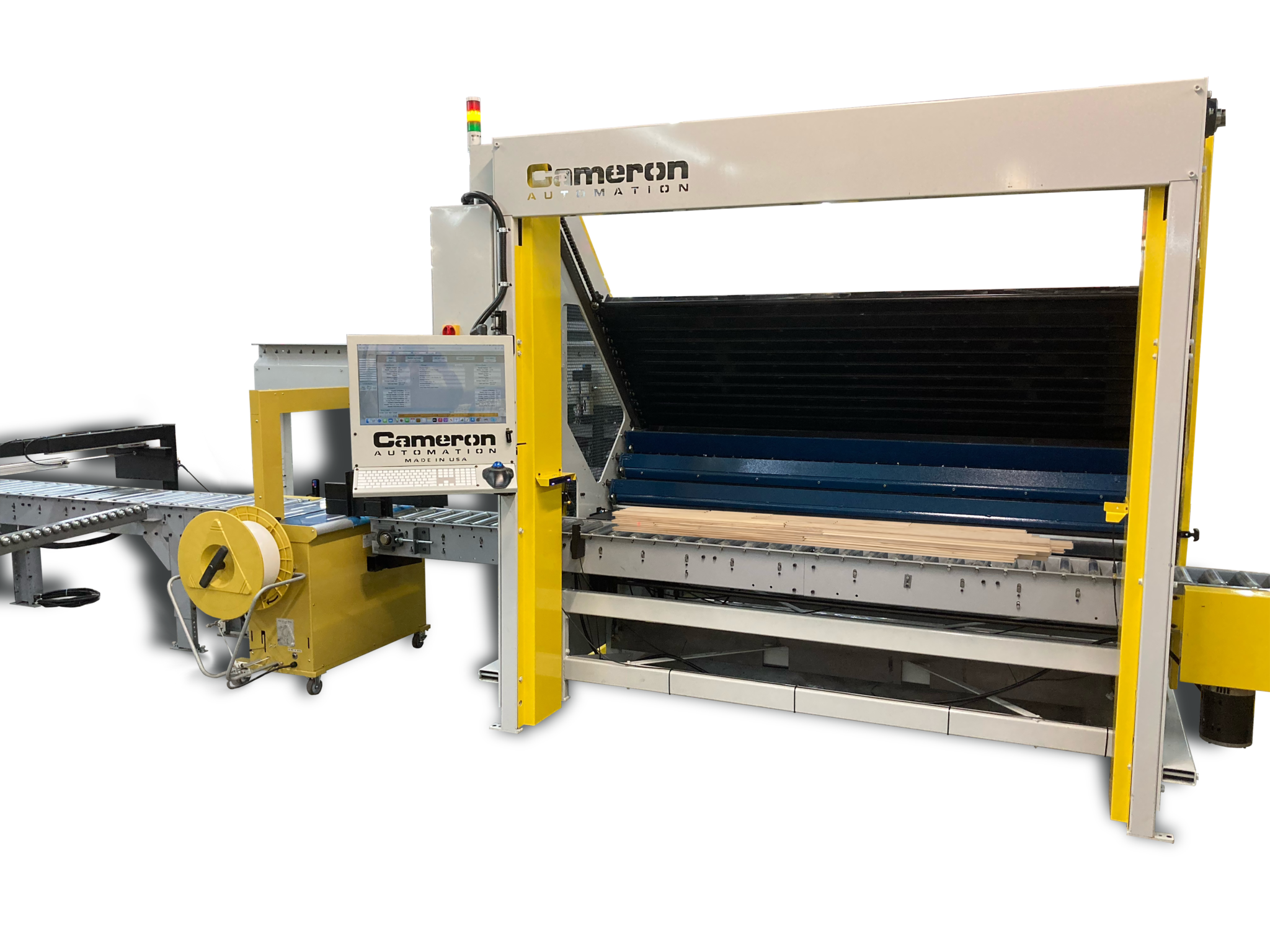

Used Quick Rip Infeed

Refurbished #34H-P2-24S-0C-R-1L-220-AS-3ML-SR-LS-HD Cameron Used Quick Rip System complete with: 1 Fixed Laser Light 3 Moving Laser Lights 16 Laser Width Scanners Length Measurement Tally System, Auto-Skew & (5) Infeed Belts & loading arms for feeding gang rip saw 16′ max length, 10/4 max. thick (1) Special 10 quarter material (1) Manual w/equipment Contact us for a quote and layout of this […]

#516A Rack & Stack

The Cameron Automation Rack & Stack The Rack & Stack is the second generation of Cameron Automation’s Flooring Nesters. Designed to nest flooring strips up to 5″ wide and bundles up to 7.5′ long, the Rack & Stack is 20% more productive, takes up 1/2 the space, and requires less operator intervention than our previous […]

#720A (#78G)- Face Frame Table

JLT’s Heavy Duty conventional Face frame Table

Align and Clamp Hundreds of Frames a day on a Tried & True Piece of Machinery

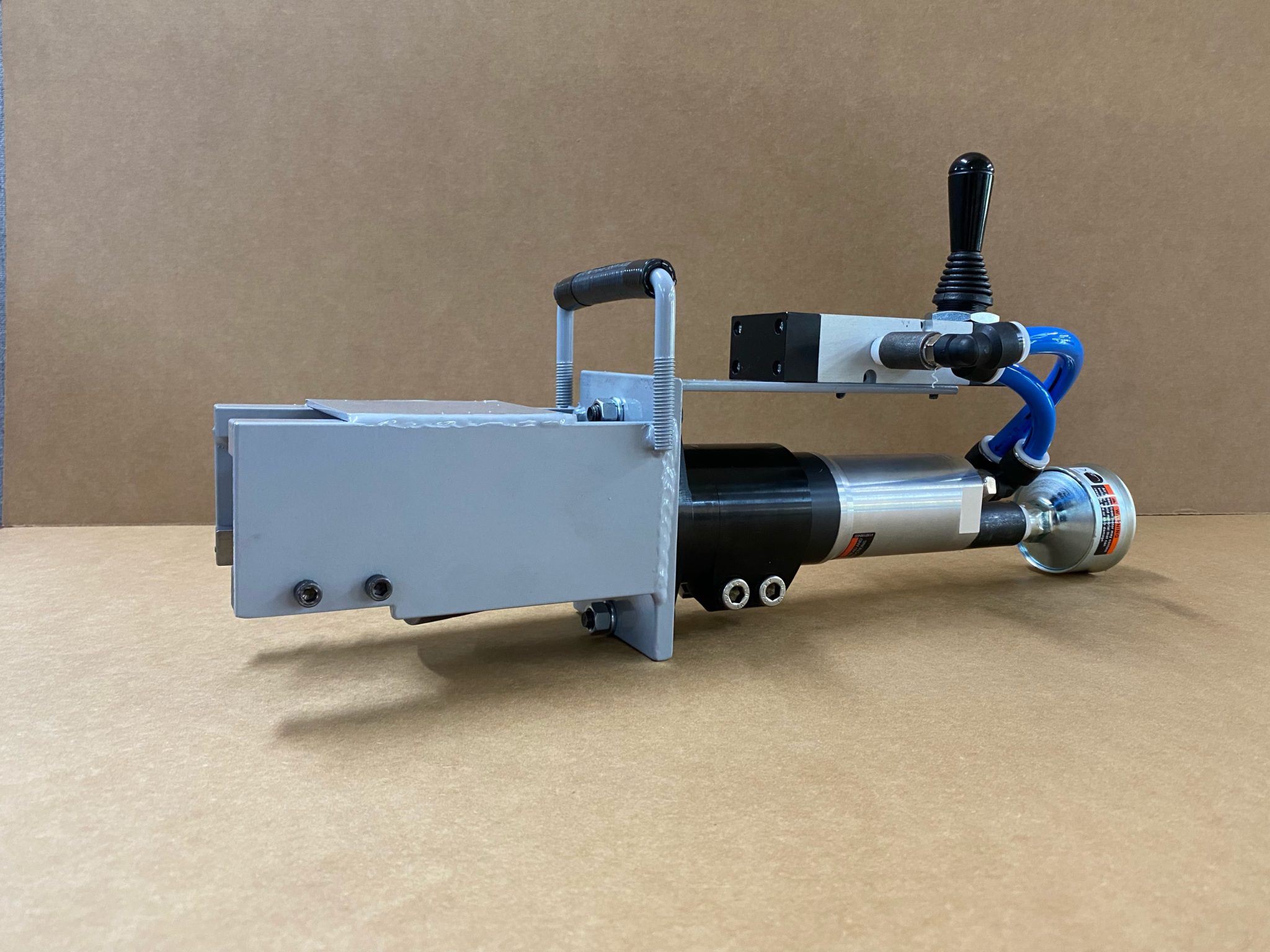

#79Z- Hand Held Pneumatic Clamp Tightener

Tightens Clamps to that Perfect Glue Line Pressure with Ease

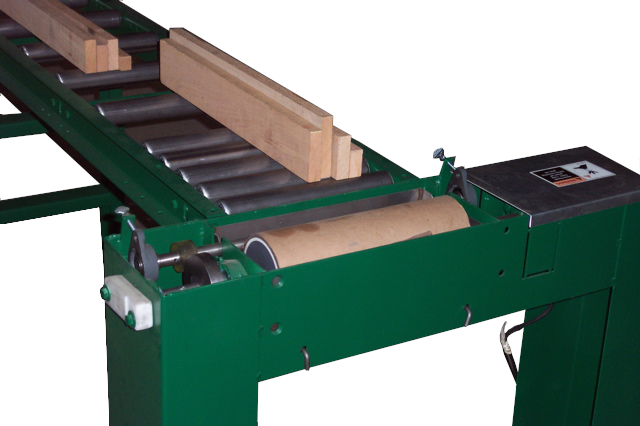

#910A- Taylor Return Conveyor for Edge Banders

Taylor Return Conveyors for Edgebanders are a solid investment for your shop. Operate your edgebander with only one operator and free up the second operator to complete other jobs.

The edge bander model comes in multiple widths and lengths. The outfeed return can be customized to return components to any location near the edge bander infeed

#138B – Plate Spreader

A simple, rugged design, designed to mechanize the glue application operation

The Plate Spreader is ideal for use with small to medium (6 section to 20 section) sized Clamp Carriers

#80U- Swing Style Clamp Carrier

The Swing Style Clamp Carrier is designed for the small and medium shop. Our simple design is easy to use and has the power to handle the big jobs

Designed for the Small and Medium Shops who produce up to 250 – 300 Panels per Day

#171B- Roller Spreader

Designed with a 13″ Wide Glue Roll, this compact stand alone unit is a great fit with any Panel Clamp, Small Carrier, or Medium Size Carrier.

Complete with a live doctor roll for a precise and adjustable glue spread. The doctor roll is adjustable and spins in the opposite direction (from the glue roll) which provides a controllable even spread

#815A / #80V – Semi-Automatic Clamp Carrier

Ideal system when a wide variety of products are to be glued, Taylor’s most versatile Clamp Carrier Design

Designed for the shops who need to Produce up to 500 – 600 Panels per day

#80Z / #80ZP – Automated Clamp Carrier

The Taylor Automated is the Industry’s Standard in Room Temperature Edge Gluing

Designed for the shops producing up to 900 – 1000 panels a day or shops that put efficiency as a premium

#30J- Conveyorized Glue Applicator

The Taylor Conveyorized Glue Applicator is designed for use with PVA type adhesives. It is equipped with a stainless steel glue pan, doctor roll, and outfeed cross bars. The glue roll is felt covered to provide even glue spread and is quickly removed for easy cleaning.

#33N- Laser Opti-Sizer

Automate your Panel Layup Process with The Opti-Sizer and save both material and labor!

The Taylor Laser Opti-Sizer is a computerized panel selection machine which is attached to a Taylor Conveyorized Glue Applicator system. It will Accurately size panels to within 1/8″ and automatically feed the Glue Applicator.

#128K- Taylor Glue Pump

The Taylor PVA Glue Pump transfers glue directly from a 55 gallon drum on the floor to the Taylor Conveyorized Glue Applicator or the Taylor Plate Spreader. It can be used with all polyvinyl and aliphatic adhesives.

#713A- Stile & Rail Door Pros

(5) and (8) Sections machines for shops that produce their own High Quality Stile & Rail Doors

PRODUCE Hundreds of Stile and Rail Cabinet Doors per day on these Models

#713A-M – Miter Door Pros

(5) and (8) Sections machines for shops that produce their own High Quality Stile & Rail Doors

PRODUCE Hundreds of Stile and Rail Cabinet Doors per day on these Models