#312A 6″ Roller Spreader

This 6″ Wide Table Top Electric Driven Roller Spreader has a precise and adjustable glue spread

#302-40-H-R JLT Clamp Arms

Additional JLT Clamps with T-Handles for Tightening

#78H- Mini Pod Press

Face Glue A variety of Solid Wood Components up to 12”Wide

Space Saving Design, Easy to Use and Precise Straight Line Clamping

#911A- Taylor Return System for Shaper Sander

Return Conveyors on a Shaper Sander have a fast payback. Most doors or panels need at least 2 passes, if not 4, through the machine to be fully machined. This normally would require (2) Operators, one to feed, and one to catch. With a Taylor Return, productivity is increased by 100% or more because it makes a (2) operator job into a (1) operator job.

The Shaper Sander model comes in multiple widths and lengths. The return can be made to match the length of your machine, and special slanted outfeeds have been designed to miss squaring bars and such on Shape & Sands.

#912A- Taylor Return Conveyor for a Straight Line Rip Saw

Return Conveyors on straight line rip saw have a fast payback. Most boards need 2+ passes through the saw, so productivity is increased by 100% or more. Usually the catch width is sized so boards can be ripped on both sides of the blade.

The Straight Line Saw model comes in multiple widths and lengths. The catch of the machine and return extension can be manufactured to fit around the bed of the saw and return the parts back to the infeed side.

#913A- Taylor Return Conveyor for Wide Belt Sanders

The Taylor Return Conveyor for use with a wide belt sander has several special features. If necessary it can be equipped with An extra transfer section to create clearance for the width of the sander, Casters on all legs allow it to be rolled away from the side of the machine for belt changes or sander maintenance, and Powered height adjustment for movable bed sanders.

Customize a Return Conveyor to fit your Sander. Models for both Fixed Bed and Movable Bed Sanders from any Manufacturer

#140C- PVA Mixer

The Taylor #140 PVA Mixer is a high capacity, fully automated Metering, Mixing and Distribution System for Catalyzed (Cross Linking) Polyvinyl Acetate adhesives

It saves labor and material by automatically pumping precisely metered quantities of PVA resin and catalyst from their original containers, mixing them without using any intermediate containers, and conveying the mixed adhesive to up to four (4) independently controlled outlets.

#128L- PVA Mixer

The Taylor #128 PVA Mixer is a simple, low cost fully automated Metering, Mixing and Pumping system for Catalyzed (Cross Linking) Polyvinyl Acetate adhesives

It saves labor and material by automatically pumping precisely metered quantities of PVA resin and catalyst from their original containers, mixing them without using any intermediate containers, and conveying the mixed adhesive to one outlet

#80Z / #80Y – Super Automated Clamp Carrier

Taylor’s Super Automated Clamp Carrier design increases the productivity over the Taylor Automated machine by 20% without any change in operation or additional floor space

Designed for Large Shops who produce up to 1200 – 1400 Panels in a day

#825A – Semi-Super Automated Clamp Carrier

The Semi-Super Automated Clamp Carrier is the high production model of our most versatile line of clamp carriers

Increase the Productivity over a Standard Semi-Auto Machine by up to 30%

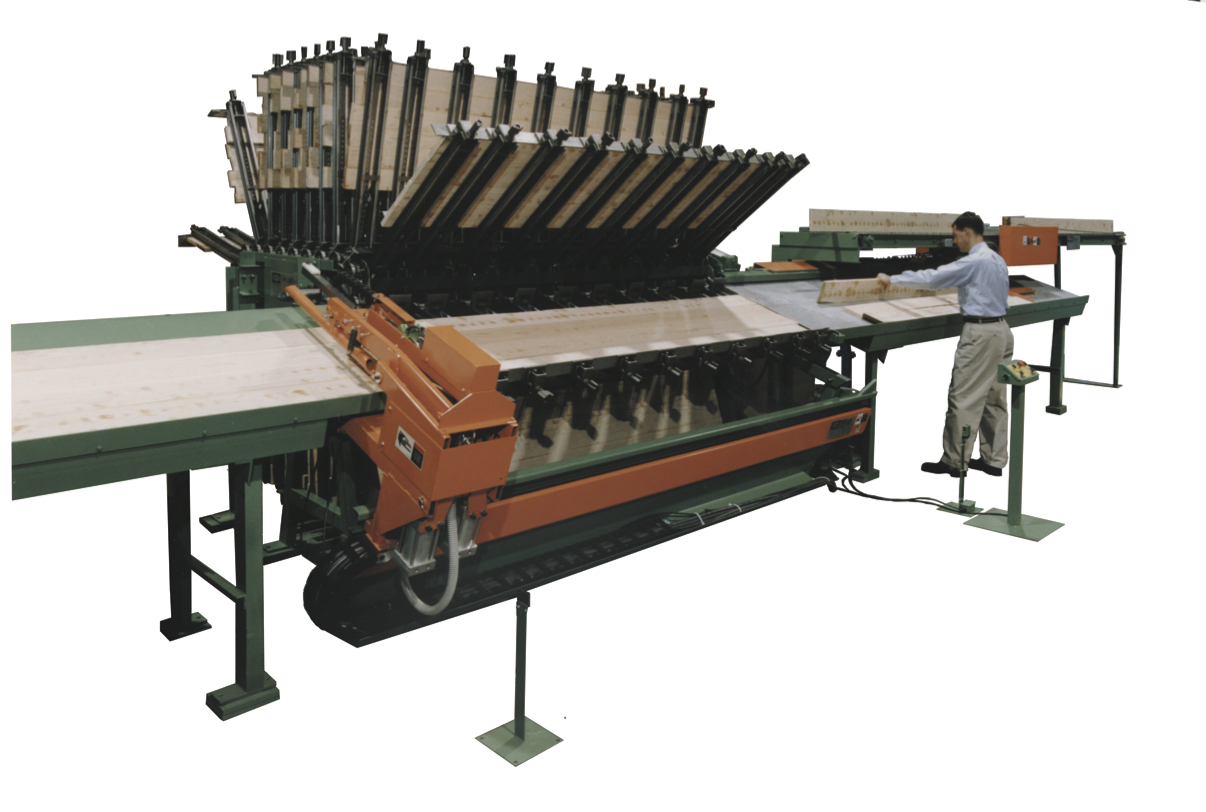

Side Loading Automated Clamp Carrier

Taylor Automated Machine for Gluing & Laminating Long Material

Efficient Continuous Flow Design to Increase Production of Beams, Posts, Flooring, Railing Stock, Molding Stock and More!!

#611A- Quick Chop Plus

High Speed, Push Feed, Optimizing Chop System designed for the Rip First AND Chop First Factories

Accurately cut door parts, face frame parts, panel staves, moldings, flooring, furniture components, stair treads, stair tread material, and much much more!!

Opti-Match

The Opti-Match is the only machine to completely automate the color matching process for high quality solid wood panels

The Opti-Match combines innovative scanning and sorting technology with complex computer programs to build and stack sized, color matched, and color blended panels, automatically

#33N- Laser Opti-Sizer

Automate your Panel Layup Process with The Opti-Sizer and save both material and labor!

The Taylor Laser Opti-Sizer is a computerized panel selection machine which is attached to a Taylor Conveyorized Glue Applicator system. It will Accurately size panels to within 1/8″ and automatically feed the Glue Applicator.

#79K-10-SP: Custom Heavy Duty Entry Door Clamp

Specialized Design for Large Doors, Large Metal Frames, Furniture Components and Windows

Custom Sizes and Configurations Available upon Request