#912A- Taylor Return Conveyor for a Straight Line Rip Saw

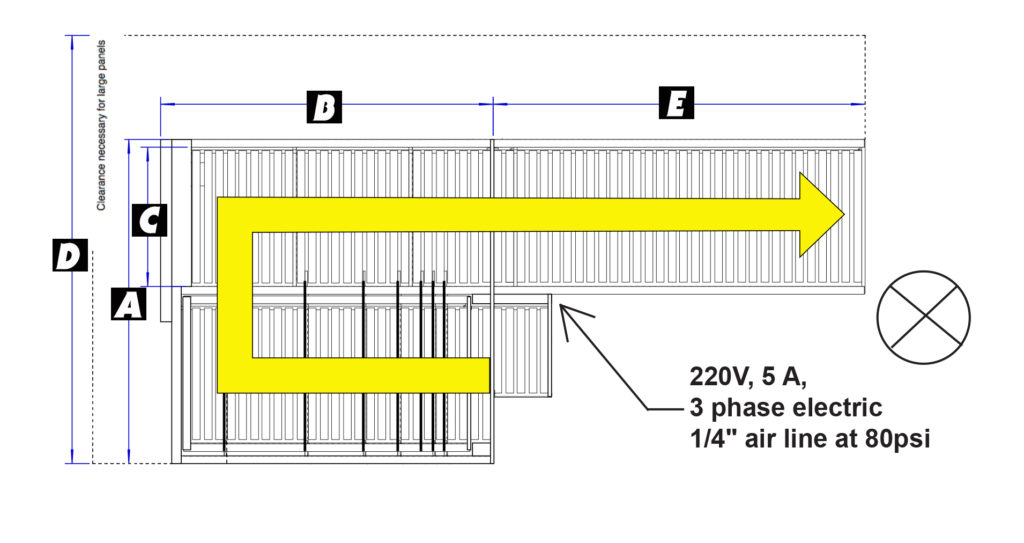

The Straight Line Saw model comes in multiple widths and lengths. The catch of the machine and return extension can be manufactured to fit around the bed of the saw and return the parts back to the infeed side.

Features:

- (3) Machine Lengths Return Material up to 60″ Long, 84″ Long, and 90″ Long

- Catch Area Widths of 36″ Wide, 48″ Wide, and 60″ Wide

- 18″ Wide, 24″ Wide, and 36″ Wide Return Sections can Return Material up to 14″ Wide, 20″ Wide, and 50″ Wide respectively

- Drop Away Receiver Gently Transfers Parts to Cross Conveyors

- Photo Eye Triggers Drop on Receiving Conveyor. A PLC Automatically Adjusts the Timing Based on Conveyor Speed

- Any Length Return (in one foot increments, measured from tail end of Straight Line Rip Saw) composed of modular sections.

- All rollers are powered and individually clutched for long belt life.

- Roller Spacing 3″ center to center.

- Variable Speed AC drive matches conveyor feed rate to rip saw feed rate.

A Return Conveyor is an Easy Machine to Justify. The Investment is not Large and every hour, day, or week that it is used saves all the $$$$ associated with one person’s salary and benefits. Return Conveyors on straight line rip saw have a fast payback. Most boards need 2+ passes through the saw, so productivity is increased by 100% or more. Usually the catch width is sized so boards can be ripped on both sides of the blade